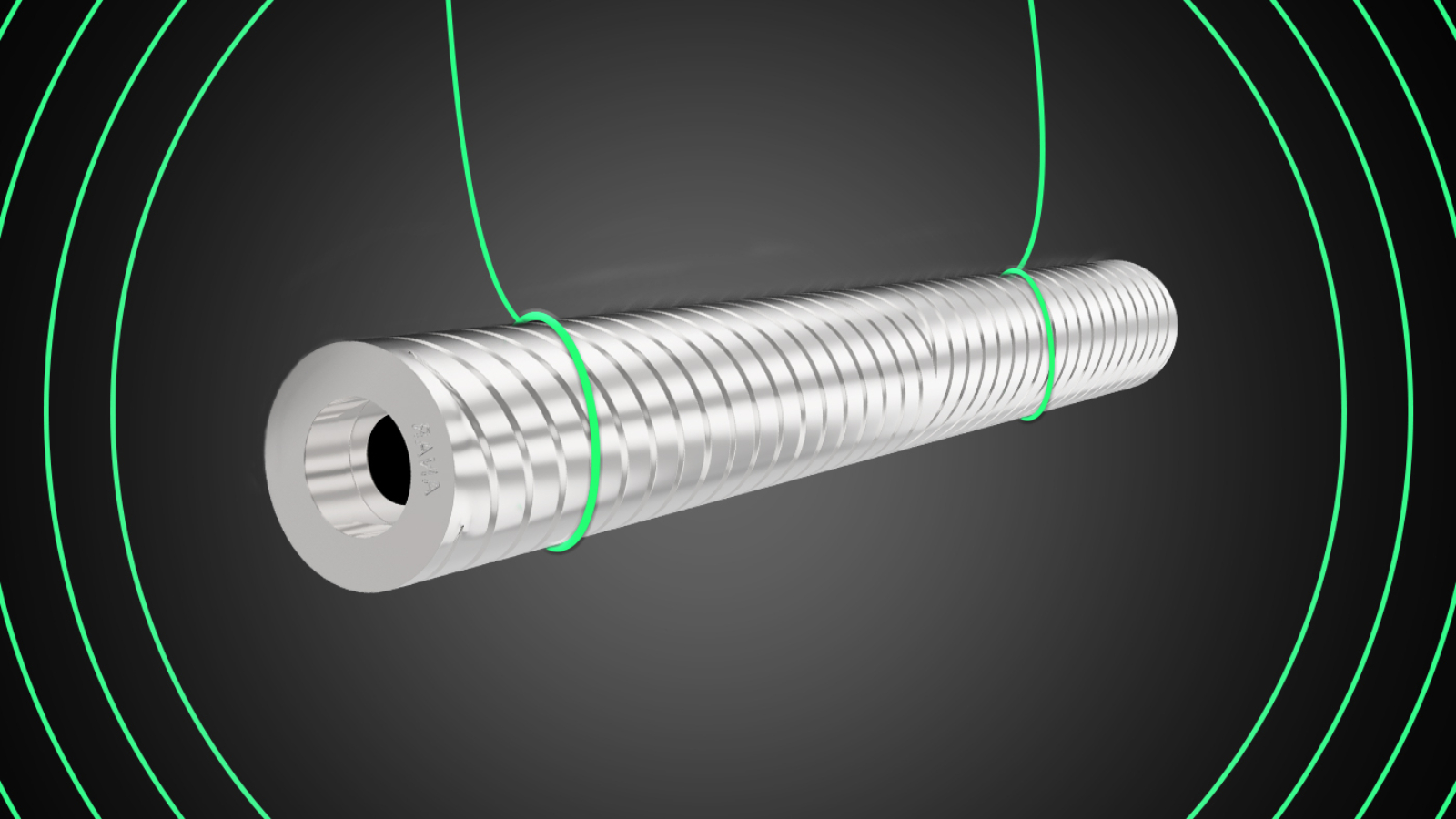

Aluminum rollers have become a cornerstone in modern industrial operations. Their versatility, durability, and lightweight characteristics make them an ideal choice for a wide range of applications, including packaging, printing, textile processing, and material handling. In this article, we’ll explore the numerous benefits of aluminum rollers in detail and explain why they are the preferred choice for many industries.

Lightweight and Easy to Handle

One of the standout advantages of aluminum rollers is their lightweight construction. Aluminum, being significantly lighter than steel and other metals, reduces the overall weight of machinery and equipment in which these rollers are used.

- Ease of Installation: The lightweight nature of aluminum rollers simplifies installation and maintenance, reducing the need for heavy lifting equipment or specialized labor.

- Improved Portability: Machines equipped with aluminum rollers are easier to move, making them ideal for dynamic industrial setups that require frequent relocation.

The lightweight property also contributes to lower energy consumption in operations, as machines require less power to drive the rollers. This translates to cost savings and enhanced energy efficiency.

Exceptional Durability and Corrosion Resistance

Despite being lightweight, aluminum rollers are incredibly durable. They are engineered from high-grade aluminum alloys, such as 6061-T6, which offer exceptional strength and rigidity.

- Corrosion Resistance: Aluminum forms a natural oxide layer that protects it from rust and corrosion. This property makes aluminum rollers ideal for industries where they are exposed to moisture, chemicals, or extreme temperatures, such as in food processing and marine environments.

- Anodized Surface: Many aluminum rollers are anodized, enhancing their surface hardness and resistance to wear and tear. Anodized rollers maintain their performance and appearance even after prolonged use.

Enhanced Performance and Precision

Aluminum rollers are designed with precision engineering to meet the stringent demands of modern industrial operations.

- Dynamic Balancing: Most aluminum rollers are dynamically balanced to eliminate vibrations during operation, ensuring smooth and accurate performance.

- High Load Capacity: Despite their lightweight nature, aluminum rollers can handle significant loads, making them suitable for heavy-duty applications.

- Temperature Resistance: Aluminum can withstand high temperatures without deforming, making it an excellent choice for applications involving heat-intensive processes, such as film production and printing.

Customization Options

Another key advantage of aluminum rollers is their adaptability to various industrial requirements. Manufacturers offer a wide range of customization options, including:

- Surface Coatings: Aluminum rollers can be coated with materials like Teflon, ceramic, or rubber for enhanced functionality. For example, Teflon-coated rollers reduce friction and improve wear resistance, while rubber-coated rollers provide better grip for handling delicate materials.

- Grooves and Patterns: Custom grooves and surface patterns can be added to optimize performance in specific applications, such as guiding textiles or gripping films during processing.

- End Fittings: Aluminum rollers can be customized with different shaft designs, bearings, and mounting options to suit unique machinery configurations.

This flexibility ensures that aluminum rollers can meet the specific demands of diverse industries, from packaging to automotive manufacturing.

Cost-Effectiveness

Aluminum rollers offer long-term cost savings for industries.

- Low Maintenance: Their resistance to corrosion and wear reduces the need for frequent replacements and maintenance.

- Energy Efficiency: The reduced weight of aluminum rollers lowers the energy required for machine operations, resulting in lower energy bills.

- Durability: The long service life of aluminum rollers further minimizes costs associated with downtime and repairs.

When considering the total cost of ownership, aluminum rollers emerge as a highly economical choice for businesses looking to optimize their operations.

Environmental Benefits

Aluminum rollers also score high on sustainability. Aluminum is a recyclable material, and most aluminum rollers are made from recycled aluminum without compromising quality or performance.

- Reduced Carbon Footprint: Recycling aluminum consumes significantly less energy compared to producing new aluminum, contributing to a lower environmental impact.

- Reusability: At the end of their lifecycle, aluminum rollers can be recycled into new products, aligning with circular economy principles.

Industries adopting aluminum rollers contribute to sustainable practices, which are increasingly important in today’s eco-conscious world.

Wide Range of Applications

The versatility of aluminum rollers is unmatched. They are used across numerous industries for diverse applications:

- Packaging: Guiding and processing materials like paper, plastic, and film.

- Printing: Ensuring precise material feed for high-quality printing results.

- Textile: Supporting delicate fabric handling without causing damage.

- Material Handling: Transporting goods in automated conveyor systems with efficiency and reliability.

Their adaptability to various environments and processes makes aluminum rollers indispensable in industrial workflows.

Conclusion

Aluminum rollers offer a perfect combination of strength, durability, and customization, making them a go-to solution for industries across the globe. Their lightweight construction ensures easy handling and energy efficiency, while their corrosion resistance and durability deliver long-term performance. With the added benefits of customization, cost savings, and environmental sustainability, aluminum rollers are a reliable and versatile component for modern machinery.

If you’re looking to enhance the performance of your operations, investing in high-quality aluminum rollers could be the solution you need. Their unique advantages ensure efficiency, precision, and durability in every application.

Leave A Comment