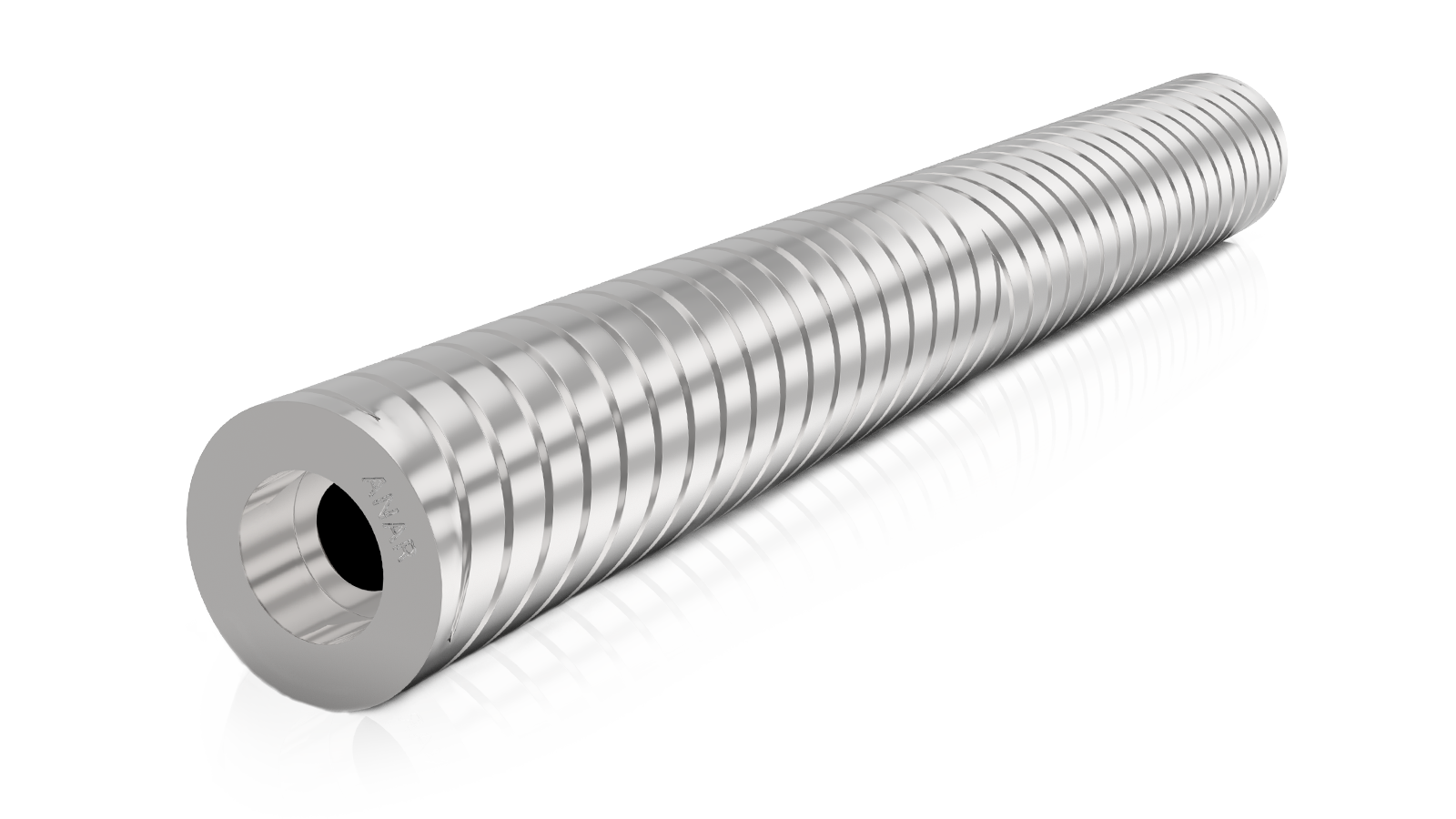

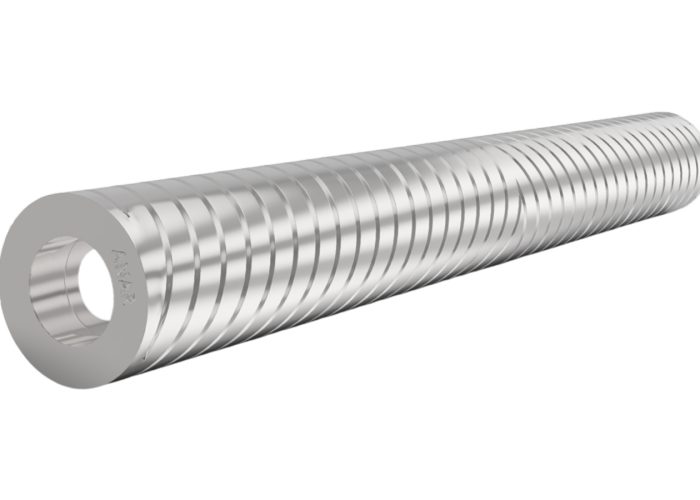

Aluminium Roller.

Lightweight and Durable

Corrosion Resistant

Heat and Chemical Resistance

Precision Engineering

Versatile Applications

Applications of Aluminium Roller

Aluminium Rollers are versatile components widely used across various industries due to their lightweight, corrosion-resistant properties, and superior performance. Below are the key applications of our Aluminium Rollers:

- Printing Industry: Ideal for web handling, gravure printing, and flexographic printing applications due to their precise balance and smooth surface finish.

- Packaging Industry: Essential in laminating, coating, and slitting processes, ensuring uniform material handling and consistent results.

- Textile Industry: Used in dyeing, drying, and finishing processes to handle fabrics efficiently without causing damage.

- Paper and Film Industry: Facilitates seamless material movement in slitting, coating, and lamination processes.

- Plastic and Film Industry: Ensures smooth handling of thin and delicate materials during extrusion, lamination, or calendaring.

- Converting Industry: Supports unwinding, rewinding, and tension control during material processing.

- Steel and Metal Industry: Used for high-precision metal sheet handling and surface finishing processes.

Contact Us for High-Quality Aluminium Rollers

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis.

Benefits of Aluminium Roller

Lightweight, durable, and corrosion-resistant, aluminium rollers ensure efficient performance, precise handling, and eco-friendly solutions for industrial applications.

Lightweight Design for Enhanced Efficiency

Aluminium rollers are exceptionally lightweight compared to steel or other metal rollers. This reduced weight minimizes energy consumption in systems like conveyors or printing machines, improving overall operational efficiency.

Corrosion Resistance for Extended Lifespan

The natural oxide layer on aluminium provides excellent corrosion resistance, making these rollers ideal for use in humid or chemically exposed environments without requiring additional coatings.

High Thermal Conductivity

Aluminium rollers exhibit superior thermal conductivity, which is crucial in applications requiring efficient heat dissipation, such as laminating, drying, and thermal processing systems.

Precision Machining for Superior Performance

Aluminium's machinability allows for high-precision production of rollers with tight tolerances, ensuring consistent performance and minimal wear in high-speed operations.

Versatile Surface Treatments

Aluminium rollers can undergo various surface treatments, including anodizing or Teflon coating, to enhance properties like hardness, friction reduction, and resistance to wear and abrasion.

Eco-Friendly and Recyclable Material

Aluminium is 100% recyclable, making it an environmentally friendly choice. Using aluminium rollers contributes to sustainable manufacturing practices without compromising performance.

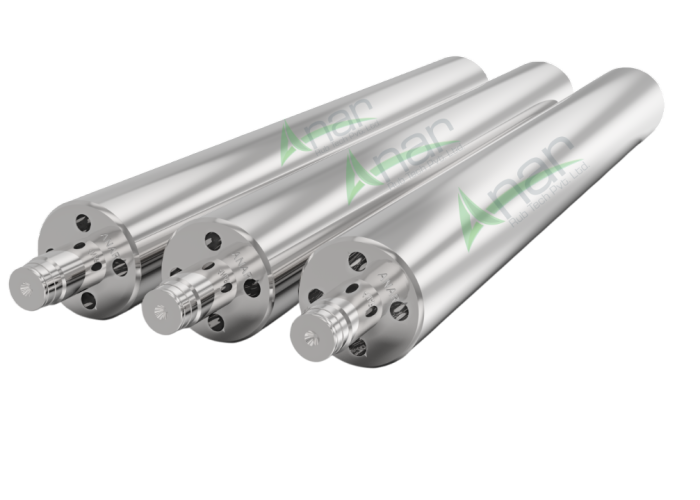

Why Choose Anar Rub Tech For Aluminium Roller?

Anar Rub Tech offers high-quality aluminium rollers with over 40 years of expertise, providing precision, durability, and custom solutions for optimal performance.

Superior Quality and Precision

We deliver aluminium rollers with exceptional craftsmanship and precise engineering, ensuring optimal performance and long-lasting durability for every application.

Customization to Meet Specific Needs

Anar Rub Tech offers fully customizable aluminium rollers, tailored to meet your exact requirements, ensuring seamless integration into your processes.

Industry Expertise and Reliability

With over four decades of experience, we provide trusted aluminium rollers backed by proven expertise, delivering consistent, high-performance solutions.